Garage doors have one of two types of springs as part of their workings. In the following overview, we’ll explore both types of springs and examine how they differ from each other.

Garage Door Torsion Springs

Torsion springs are the more common type of springs and are being used in modern roll up and sectional garage doors. Garage door torsion springs come in many different sizes and are located horizontally, on the torsion tube above the garage door.

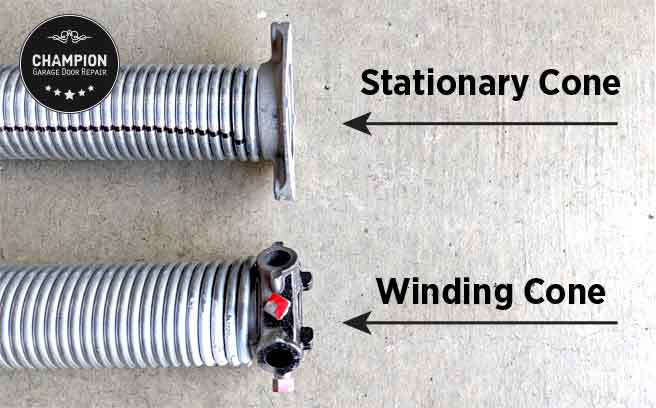

Unlike extension springs, torsion springs are beefier and equipped with two cones on the ends of their coil; a stationary cone and a winding cone. The most common used torsion springs for residential garage doors are as follows.

- Regular non-insulated garage doors: 207 x 1.75” x 27”, or 218 x 1.75” x 28”.

- Insulated poly back garage doors: 218 x 1.75” x 28”, or 225 x 1.75” x 28”.

- Insulated steel back garage doors: 234 x 1.75” x 30”, or 243 x 1.75” x 33”.

- Wood and full view garage doors: 243 x 1.75” x 31”, 250 x 1.75” x 33”, 262x 1.75” x 38”, and various of custom springs.

Different garage doors have distinct properties and requirements, thus, require different springs sizes. For example, insulated garage doors with a higher R-value and denser insulation material can be heavier, requiring springs with a higher torque output. When replacing springs, always adhere to the manufacturer’s recommendations. Measure your existing torsion springs accurately with designated micrometers and purchase the same size for replacement.

Torsion springs can be converted and replaced with torsion springs that have different properties such as gauge, length, and inside diameter. However, it’s crucial that the replacement spring generates an equal torque output to maintain proper balance for the door. Consult a licensed garage door repair company or certified spring manufacturer for accurate spring conversions.

Garage Door Extension Springs

A less common type of garage door springs is the extension springs. Two types of garage door applications use extension springs. The first is sectional garage doors, where the springs are located above the horizontal tracks. In this application, the springs are connected with cables from the door’s bottom brackets to an anchor at the end of the horizontal tracks. The second application is tilt-up or one-piece garage doors, where the springs are located on the sides, connected to the door hinge and the jamb.

Unlike torsion springs, extension springs support the garage door weight by generating a pulling force. They are stretched when the door is closed and slowly contract when the door opens. Although the spring sizes vary from door to door, the most common sizes of extension springs in residential garage doors are: p928, p728, p528.

How Torsion Springs Differ from Extension Springs

Torsion and extension springs differ in their design, placement, and how they function. Here are the key differences between the two, their advantages and disadvantages.

Mechanics

Torsion springs generate rotational force or torque, which is transferred to the drums at the ends of the torsion tube, lifting the garage door. This rotational force offers more control, resulting in a smoother door movement. On the other hand, extension springs generate pulling force, creating a more linear force and a jerky motion during the door’s operation.

Configuration

Torsion springs are mounted horizontally above the garage door, available in either a single or double configuration based on the weight and size of the garage door. These springs wind up when the door is closed and unwind as the door opens. Extension springs, on the other hand, are mounted vertically on both sides of the garage door and are installed in pairs. They extend when the door closes and contract as the door opens.

Maintenance

Torsion springs are adjusted using designated winding rods, with calibration done through the spring’s winding cone. They are more expensive than extension springs, and their replacement process is typically more complex, labor-intensive, and requires specialized tools.

Adjusting extension springs involves adding or removing tension through the cable system. In single-piece (tilt-up) garage doors, adjustments are made to the door’s hinge or the chain that connects the spring to the jamb. The replacement and repair process is generally easier and faster.

Understanding Balance Principles of Torsion and Extension Springs

When extension springs are used to counterbalance a garage door, they operate based on Hooke’s Law, which describes the correlation between the force applied to a spring and its resulting displacement. Hooke’s Law states that the force exerted by a spring is directly proportional to the displacement of the spring from its equilibrium position. Mathematically, this relationship is expressed as “F=−kx”, where:

- F is the force exerted by the spring.

- k is the spring constant, represents the spring’s stiffness.

- x is the displacement of the spring from its equilibrium position.

When a garage door is supported by extension springs, the weight of the door applies a force on the springs, causing them to stretch or compress. The springs then exert an equal and opposite force (according to Newton’s third law of motion) to try to return to their equilibrium position. This force is what helps counterbalance the weight of the door.

In the case of a torsion spring, the force exerted is a torque or rotational force, which is proportional to the angle of twist (θ) rather than linear displacement. This relationship is mathematically expressed as “τ=kθ”, where:

- τ is the torque applied to the spring.

- k is the torsional spring constant, represents the spring’ stiffness.

- θ is the angular displacement from the equilibrium position.

Despite the difference, the principle remains the same.

Can You Replace Extension Springs with Torsion Springs?

Extension springs can be replaced with torsion springs. In fact, if you have sectional garage doors that use extension springs, it’s advisable to replace the extension lift system with torsion assembly for the following reasons:

- Increased Safety: Torsion springs are considered to be safer than extension springs. Torsion springs are mounted on the torsion tube, reducing the risk of injury in case of spring failure or entrapment.

- Smooth Operation: Torsion spring systems provide smoother and more controlled door movement, resulting in less vibration and noise during the opening and closing of the garage door. Additionally, this can lead to reduced wear and tear over time, potentially extending the lifespan of the garage door.

- Adjustability: Torsion springs are adjustable, enabling precise fine-tuning for optimal garage door balance. This adjustability improves performance and reduces the likelihood of operational issues.

- Compatibility with Heavy Doors: Torsion springs are ideal for heavy garage doors since they are specifically designed to handle substantial loads more effectively than extension springs, making them suitable for insulated, custom wood, and full-view garage doors.

- Parts Availability: The market is shifting towards torsion spring systems, and with the decreasing popularity of extension spring systems, there might be instances where parts for these systems become less readily available. This could include specific types of extension springs, pulleys, cables, and other components.

The decision to transition from an extension lift system to a torsion assembly is typically influenced by various factors. The suitability of each system depends on the specific characteristics of both the garage structure and the garage door. For example, certain garages may have limited headroom or backroom, which can restrict the options that can be used.

Do Torsion Springs Last Longer Than Extension Springs?

Not necessarily. Contrary to the common assumption, the lifespan of torsion springs versus extension springs is not solely determined by their type. There are situations where extension springs may actually outlast torsion springs.

The durability of both types is influenced by various factors, including correct sizing and proper installation. Springs that are improperly sized or installed may experience premature wear and reduced lifespan, regardless of their type. Additionally, environmental conditions, including inadequate weather sealing and exposure to extreme temperatures, humidity, and corrosive elements like salty air, can impact the overall longevity of garage door springs.

Knowing Your Garage Door Springs

Knowing what type of springs your garage door system uses enables you to follow the manufacturer’s recommendations for lubrication, inspection, and other maintenance tasks. This knowledge can help you in making informed decisions about replacement, upgrades, or modifications to your garage door system. Understanding the mechanics also allows you to research proper repair practices, safety procedures, and enables you to provide accurate information when seeking professional help for repairs.